What is the growth potential of your market?

For industrial inspection work, it is huge. The vertical sectors in which we operate include renewables, oil & gas, rail infrastructure and power transmission. Each of those markets is growing very, very quickly. Wind, rail and transmission are the biggest ones in terms of overall market size. Oil & gas and utilities have been the main areas where Cyberhawk has focused its efforts in recent years.

We are an inspection company, focused on the provision of information. We are engineers. We collect data - and that could be done by using a drone or by having a man on the ground. We process that data. We add a lot of value by processing it and producing reports and analysis. For instance, we will look at a power line with 300 towers and assess every individual component, before inputting this information into a map-based asset management system.

In certain applications, our inspection techniques save millions of pounds on each individual inspection. An example of this is when we do flare inspections at oil refineries. The flare is a safety critical part of the process plant, designed to burn off all of the hydrocarbon inventory in a process plant if there is a problem, this is called a blowdown. Traditionally, the only time a flare could be inspected is during a planned process shutdown. However, this can cause an extension to the shutdown period for the plant if a problem with the flare is discovered. With our ROAVs, we can look at the flare whilst the plant is still live, which allows the plant operator to plan any repair or maintenance work that the flare requires prior to shutdown, rather than getting a surprise during the shutdown itself. Tens of millions can potentially be saved, when you consider an example of seven days of shutdown on a plant, at a cost of £2m a day.

On a transmission inspection, these inspections would normally been carried out by a technician climbing up the pylon tower. They normally turn off the power on one side of the pylon to do that - and this could only be done for a short amount of time at certain periods. We can undertake the entire inspection while it is on line.

In the wind sector, our model for inspecting wind turbines is around four times quicker compared with traditional methods such as rope access.

You work in over 20 jurisdictions. What are the issues you face on regulation?

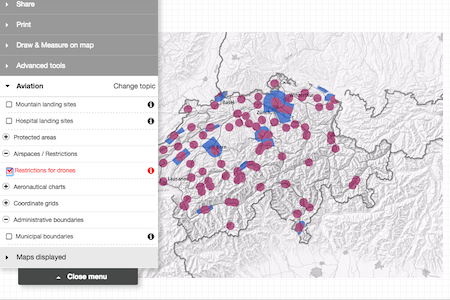

The biggest frustration is the difference in regulation between different countries. It’s different in each jurisdiction. Some are quite similar to the UK but, even in Europe, there are massive differences. In some countries there are prohibitions. In the Netherlands, for instance, it’s not legal to fly a drone commercially but we have an exemption. We got the exemption because we are safe and take people out from working at height. The Dutch government is happy with that.

Having to work within visual line of sight is another issue. Some projects - like doing a pipeline inspection - would mean going outside the line of sight. But you can’t do that now in the places we operate - with the exception of France. It’s going to be a while before we see it. There are hundreds of millions of miles of pipelines where this could be used. Typically, it is now done by guys driving along or by manned helicopters, however those are very expensive operations. And in Canada, for instance, there are huge pipelines going through the wilderness. Companies are very nervous about sending manned aircraft there because there could be a real problem if there is an accident. They are very keen to use drones as an alternative.

How do you view the specific plans to harmonise laws in Europe?

EASA [the European Aviation Safety Agency] is coming up with a framework for harmonisation, based on the Riga Declaration. What we have seen on paper looks quite sensible. It’s a good balance between making sure there’s a high level of safety, without having very prescriptive legislation that can stifle a business’s chances of operating successfully.

The next goal is to get something in the ICAO [International Civil Aviation Organization]. That will probably be more of a challenge because there are 192 member states to corral with very different views, and each state has a veto. There are massive, massive opportunities in the US, for instance, but there have been big difficulties in entering this market. We have addressed this by partnering with people operating UAVs there instead, which allows them to capture the data required whilst we can analyse and report on this data from our inspection centre.

How much of an issue is privacy now?

Not so much. Oil refineries are not generally next to houses. The only places that we potentially have privacy challenges are where there are members of the public in the area. It’s only been a challenge for us on a couple of commercial jobs such as building inspections in public areas.

But data protection is going to become more of an issue. There is a lot of knee jerk lobbying. A lot is aimed at the hobby users of UAVs and, maybe, at journalists using drones to snoop on people. We could unfortunately get disrupted by the same legislation.

How will aviation enforcement issues develop?

Over the next few years aviation authorities will probably wash their hands of the smaller systems (sub 4kg) and push enforcement of that onto the police because the volume of traffic is going to be hundreds of times that of unmanned aircraft. In five years we will be seeing drones everywhere.

Which are the best places to operate from a regulatory point of view?

The UK is up there, without a doubt. It’s got one of the most permissive and pragmatic approaches to regulating. A lot of countries are trying to mirror what the UK has done.

In the US, the vision of the Federal Aviation Administration is very much to make the regulation very permissive. It will be a polar change. It will likely become even more permissive than the UK.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)